Ergonomic Guidelines For Manual-handling Trolleys In The Health Industry

A manual handling operation may be defined as 'any transporting or supporting of a load (including lifting, putting down, pushing pulling, carrying or moving thereof) by hand or bodily force'.

Approximately one third of all injuries reported to the enforcing authorities are due to incorrect manual handling. Over £100million a year is lost due to injuries at work associated with incorrect manual handling. A major contributor factor is the lack of proper training, supervision, information and instruction.

Health; Applying Manual Material-Handling Guidelines to Job Tasks. How much can your employees safely lift, push or pull? Our experts review the often conflicting guidelines available and offer simple 'rule-of-thumb' procedures to follow.

Legislation

- The Manual Handling Operations Regulations 1992(amended 2002)

Statutory Instrument 2002 No. 2174

The Health and Safety (Miscellaneous Amendments) Regulations 2002 © Crown Copyright 2002

Injuries associated with manual handling

Injuries to discs, ligaments, muscles, etc are of a cumulative nature rather than being attributable to any single handling incident. 90 percent of back troubles are attributable to disc lesions which cause 'pinching' pains. Ligaments and tendons may tear. Hernias may develop after straining the muscle wall tissue. Dropping objects on body parts can cause fractures, abrasions and cuts, etc.

Injuries during manual handling operations are caused by incorrect lifting (forces of compression made on spine, ligaments, and tendons); pushing and pulling (high stresses exerted on the body when pushing rather than pulling); and, carrying (muscles may tire depending upon how the load is being carried).

Common manual handling statistics connected with injuries are:

- 65 percent strains

- 9 percent superficial

- 7 percent other

- 7 percent contusion

- 7 percent laceration

- 5 percent fractures

Sites of injury caused by incorrect handling are:

- 45 percent back

- 16 percent finger/thumb

- 13 percent arm

- remainder affecting lower limbs, arms, torso

Reducing the risk of injury

- carry out a risk assessment

- lifting whilst bending forwards can be four times more stressful than lifting with an upright back

- adopt an ergonomic approach in the design of manual handling operations as a whole - fit the operation to the individual and not the individual to the operation

- use mechanical assistance - levers, hoists, trolleys etc

- involve the workforce

- refer to industry specific guidance

- improve the task

- provide personal protective equipment as a last resort

- reduce risk of injury from the load by smaller loads, known weights, no sharp edges etc

- improve the working environment - good housekeeping, flooring, lighting etc

- individual selection - fitness, strength, build etc

- produce a check list

- provide training

Manual handling assessment

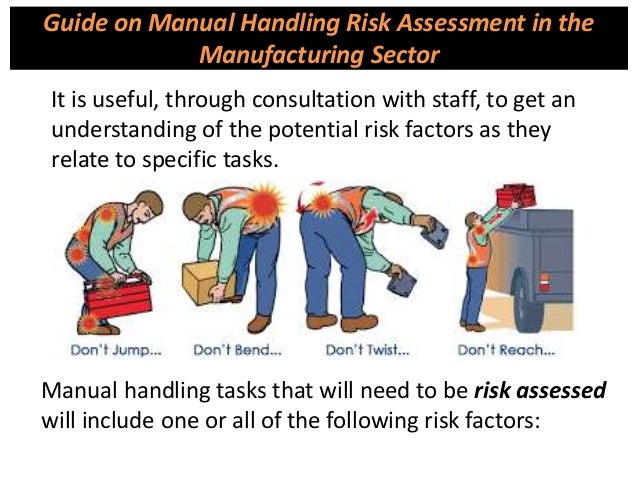

Risk assessments are required under health and safety regulations. Employers must take into account the task, load, working environment and the individual capability. See further information below for a useful guide to carrying out manual handling assessments.

The Chartered Institute of Environmental Health runs courses on manual handling. Visit their website for details.

Further information

- Getting to grips with manual handling, a short guide for employers[PDF] (file size 230Kb) Health and Safety Executive (HSE), ISBN 0717617548

The guideline is for a minimum diameter of:

125mm (5”) for non-patient trolleys

175mm (7”) for patient trolleys used indoors

200mm (8”) for trolleys used out doors or for loads over 200kg (485lb) Smaller castors can still be used in restricted circumstances, for instance, use on lightweight equipment.

In general, castors of:

100mm (4”) size are recommended up to 120kg (265lb) trolley loads, but only on smooth floors and for short distances. They can be used on ward furniture, but not on catering or hospitality equipment.

75mm (3”) are even more restricted, being recommended only up to 100kg (220lb) trolley loads and again only on smooth floors without obstructions for short distances.

50mm (2”) are recommended only up to 80kg (175lb) trolley loads and for very short distances.

If used on carpets a maximum load of 50kg (110lb) is appropriate.

The research is absolutely clear: large diameter wheels reduce forces for all trolley movements. Larger wheels:

Are easier to roll along the length of corridors, over ridges, e.g. at the edge of carpets, into lifts

Reduce vibration to patients and equipment and minimise shock transferring to the user’s arms from impacts

Are more robust/resistant to damage, remain functioning efficiently for longer than smaller wheels.